150kHz

Switching frequency600000rpm

Maximum speed≤0.2%

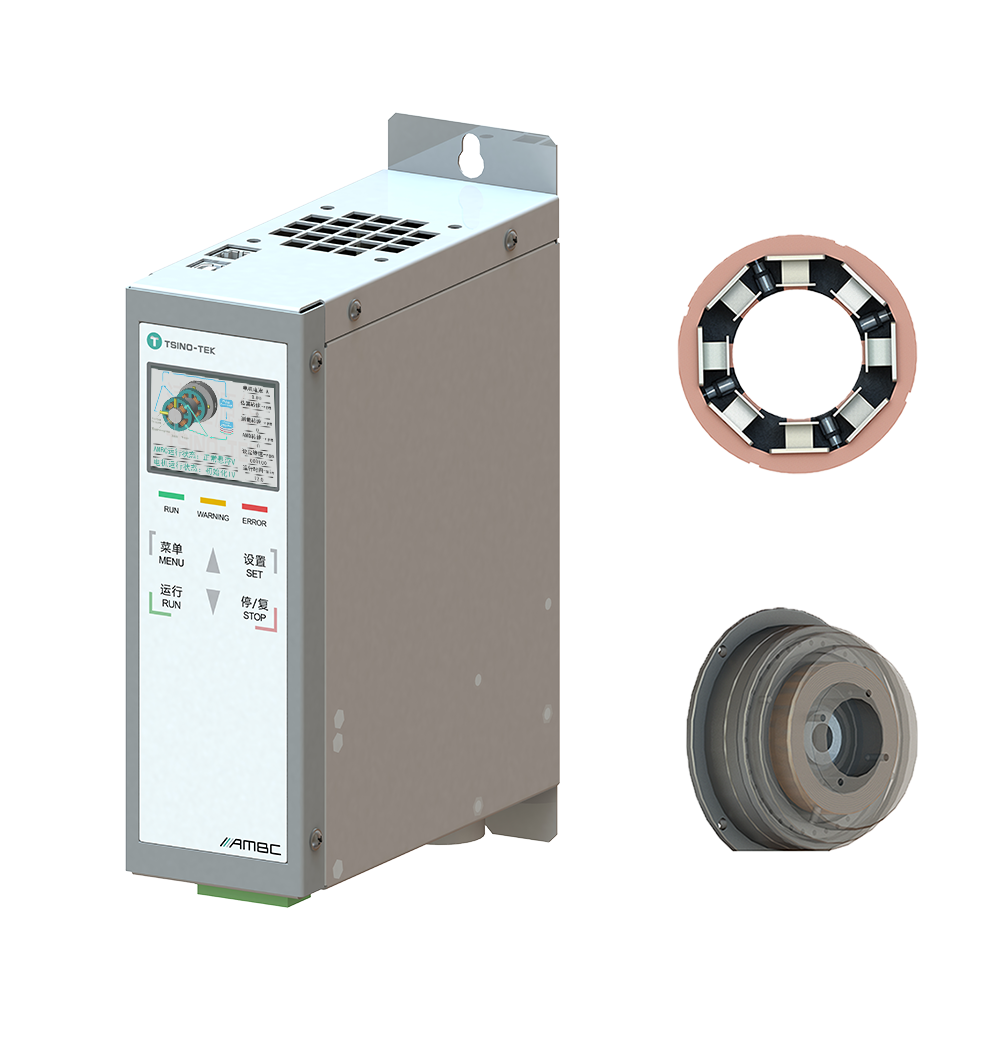

Rotational speed accuracyThe TSD-DCHSF is a high-performance high-speed motor vector driver with an output fundamental frequency of up to 8000Hz and can drive a high-speed motor/spindle at 480,000 rpm. The motor can achieve high-performance sensorless vector control without encoder, which has the characteristics of high speed accuracy, fast dynamic response, and no drop speed with load, which significantly improves the processing performance. At the same time, the small current harmonic can also significantly reduce the temperature rise of the motor/spindle and ensure the safe operation of the motor/spindle.

The TSD-DCHSF product has an input voltage of 72VDC and can be powered using a switching power supply. The output voltage is 40V and the rated output power is 800VA. This series of products has a variety of communication methods, supportING IO/RS485/CAN.

TSD-DCHSF products have been widely used in PCB drilling and plate splitting machines, denture cutting equipment, zirconia ceramic processing equipment, high-precision grinding machines, high-precision engraving and milling machines and other occasions that require the use of high-speed motor systems, which greatly improves the performance of customer processing products.