120000rpm

Rotate speed70dB

Noise≤0.2%

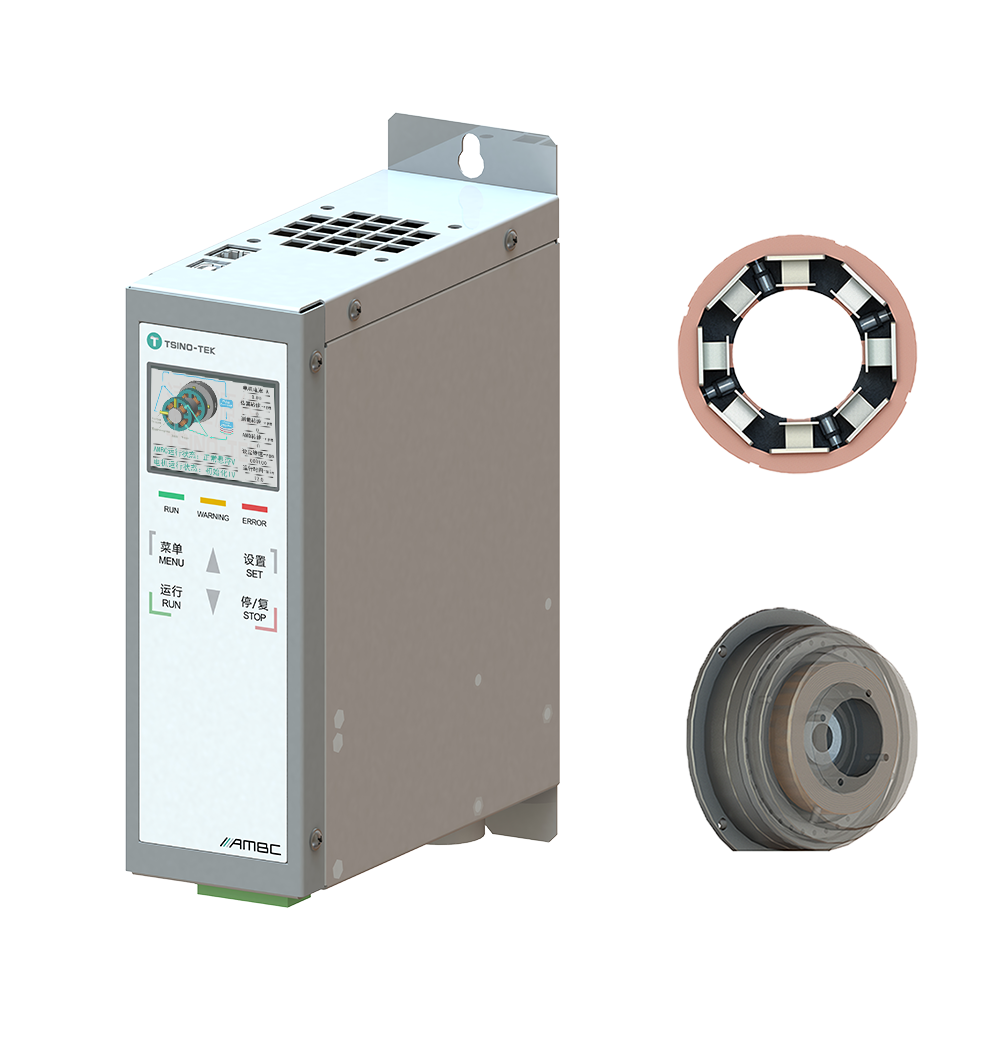

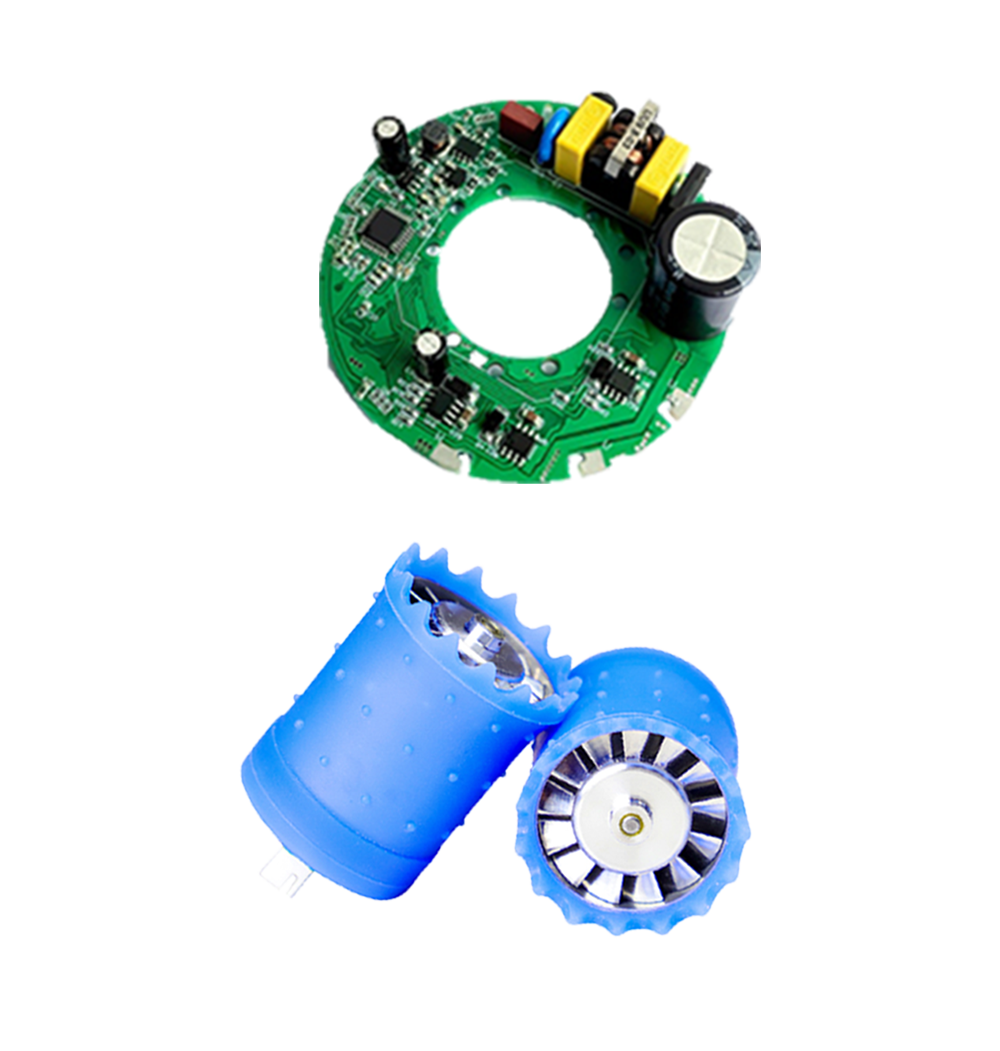

Rotational speed accuracyThe TSD-CM series provides customized high-performance electric drive solutions for high-speed rotating motor scenarios such as hair dryers, vacuum cleaners, electric fans, power tools, pumps, and compressors with a speed of less than 300,000 rpm.

TSD-CM adopts FOC Hall-free sine wave vector control technology, leading the common technology on the market (with Hall/F square-wave control) generation, accurate control, small torque ripple, so that the motor runs smoothly at high speed, low noise and low vibration, and the user experience is good. Hall-free design, through advanced software algorithms to accurately position the high-speed rotor, replace the use of traditional hardware sensors, reduce the hardware cost of the system, and improve the reliability of the system. At the same time, the driving current harmonics modulated by the sine wave control algorithm are much lower than the traditional square wave control, which avoids the additional torque ripple caused by the square wave drive, which is conducive to the noise reduction and vibration absorption of the motor.