0755-23321087

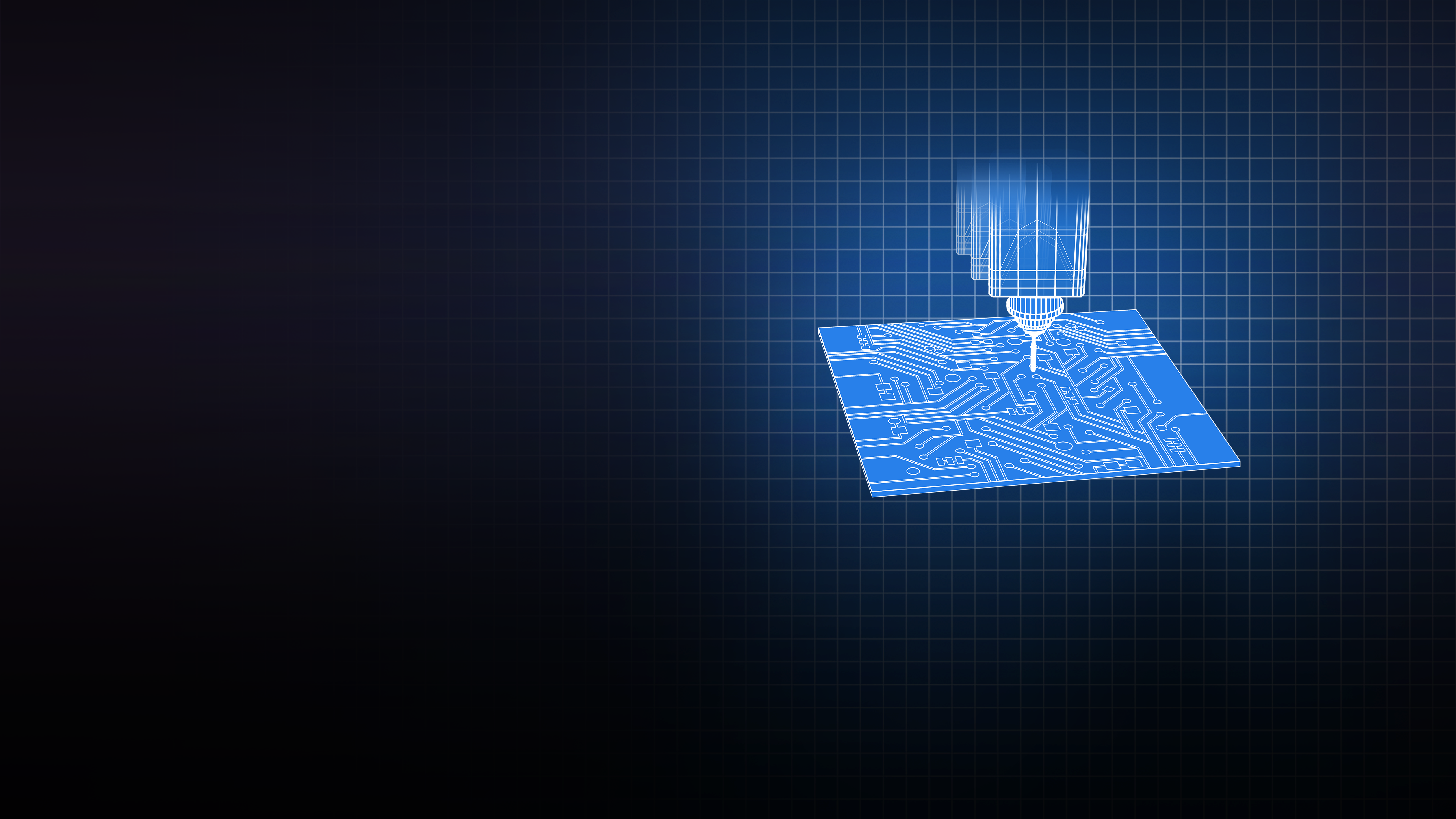

Founded in January 2018 and headquartered in Haidian District, Beijing, Tsino-Tek (Beijing) Co., Ltd. mainly develops and produces ultra-high-speed motors/electric spindle drives, with a maximum drive speed of 480,000 rpm, using high-precision sensorless vector control technology to drive AC induction motors, brushless DC motors and permanent magnet synchronous motors. Products are widely applied in national strategic fields of semiconductors, 3C processing, high finishing, new energy etc., mainly suitable for: dicing machines, PCB drilling and cutting machines, denture engraving equipment, zirconia ceramic processing equipment, turbomolecular pump, high-precision grinding machines, high precision engraving and milling machines, high-speed centrifugal blowers, air compressors for hydrogen fuel cell, high-speed compressors and other occasions that demand the employment of high-speed motor systems.