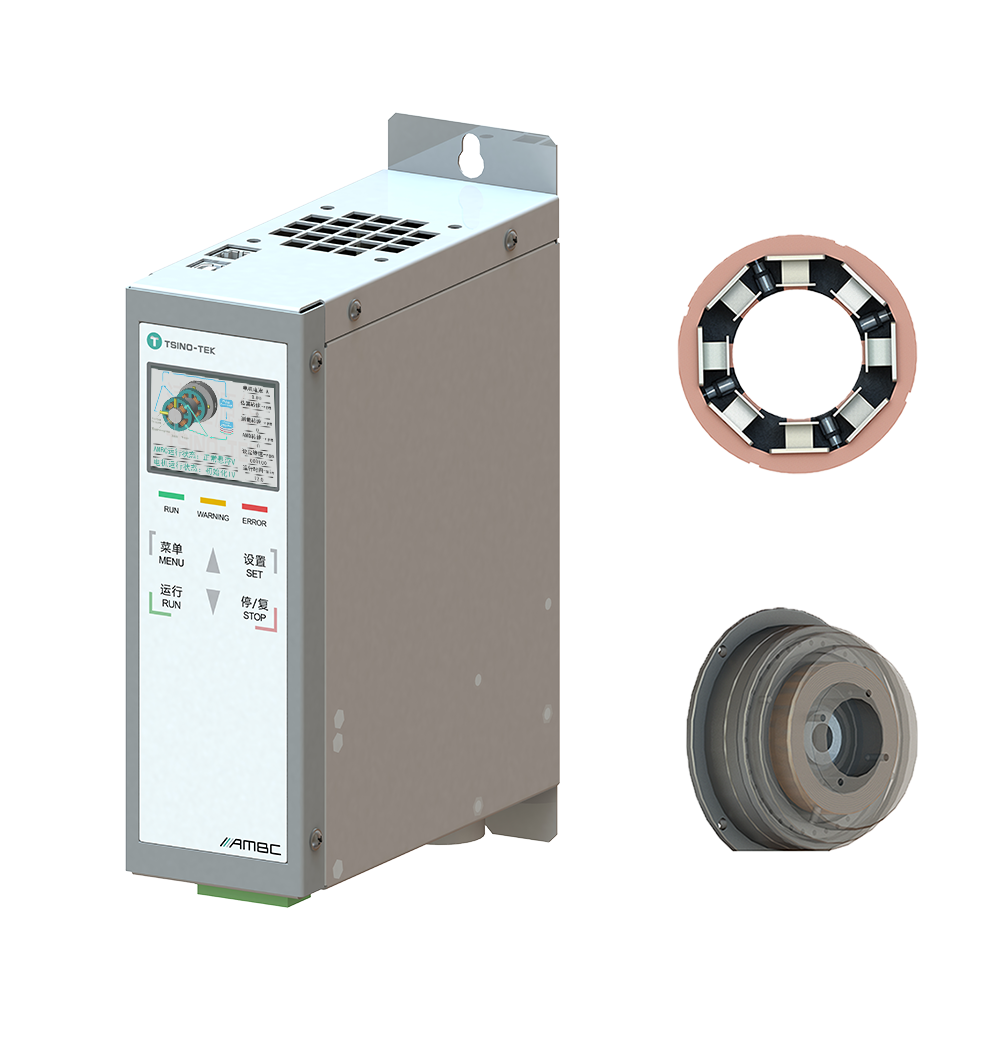

64kHz

Switching frequency480000rpm

Maximum speed≤0.2%

Rotational speed accuracyTo meet the diverse needs of our customers' applications, the HP2S Family offers the following benefits:

(1) User programmable and background software monitoring function, support I/O control, CAN communication, 485 communication, etc., and at the same time control the motor by displaying the operation handle (optional), the combination function is powerful and the performance is stable;

(2) Built-in brake crystal, combined with simple brake resistance, can improve brake torque capacity;

(3) DC 24 V external power supply optional external supply, through the DC 24 V external power card external power supply, can be continuously powered when the main power supply is abnormal, to ensure continuous communication after the main power supply is powered offdown;

(4) Built-in STO (Safe Torque Off) safety stop function, with high safety specifications;

(5) Seamless side-by-side installation provides high configuration flexibility and improves installation efficiency in the operating environment of -20°C~40°C.