0755-23321087

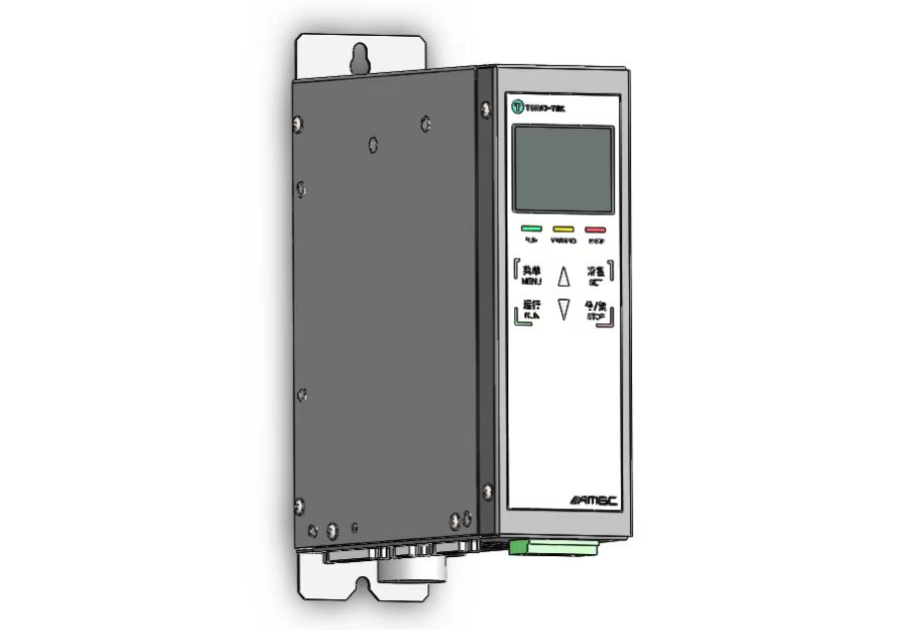

Compared with conventional ball bearings, magnetic bearings have significant advantages in the high-speed field. Magnetic bearings do not require grease lubricationand have no pollution, no contact, no wear, corrosion resistance, high efficiency, variable damping and other characteristics. In order to be able to meet the customer's application of AMB, Tsino-Tek newly developed a series of magnetic bearing control units AMBC. The series of TSD-AMBC is a high-performance magnetic bearing controller developed for magnetic bearings that uses an acceleration algorithm based on SoC FPGA hardware with control frequencies up to 64kHz to drive five-axis magnetic bearings. The TSD-AMBC series is available in a variety of models with different power ratings to meet the needs of a wide range of machines.

In terms of magnetic bearings, we have the following advantages

一、Non-contact support

When designing high-speed rotating machinery, Tsino-Tek's active magnetic bearings offer unique advantages over conventional ball bearings or oil-film bearings. Unlike conventional bearings, AMB suspends the target rotor in a magnetic field, thus guaranteeing a non-contact rotor support system with extremely low friction and no contact wear. Some of the benefits of non-contact magnetic bearings include:

Low power loss and heat generation

Higher achievable speeds

Low noise

二、 Low vibration

Tsino-Tek utilizes an self-adaptive synchronous force suppression algorithm to minimize vibration from the rotor to the housing. Low vibration is important in high-precision applications related to the food, medical and defense industries. Benefits of low vibration transfer rates include:

Minimized vibration of magnetic bearing structures;

Reduced dynamic load on magnetic bearings;

Reduced AMBC power consumption;

Significantly reduced noise;

三、Health monitoring and diagnosis

Tsino-Tek's active magnetic bearing products are simple to set up and allow users to monitor the health of their magnetic bearing systems. Tsino-Tek's AMB includes a position sensor, actuator and a microcontroller that makes machine health monitoring and diagnostics easy to monitor. By connecting to an external computer, advanced diagnostics can be used to identify, analyze and archive the health and historical performance of your machines.

Easy monitoring via real-time vibration;

Capable of monitoring bearing loads on all shafts

Ability to record advanced data and fault logging

An optional data acquisition plug-in provides higher quality and higher resolution data

四、Advanced integrated machine design methods

Tsino-Tek leverages extensive multidisciplinary interdisciplinary expertise to design magnetic bearings with customers, rather than simply providing magnetic bearing assembly components, which guarantees excellent performance of the magnetic bearing in the system. Some of Tsino-tek's competitive advantages include:

A wide range of areas of expertise, including mechanical, electromagnetic, rotordynamics, thermal and power electronic design and analysis;

Improved proprietary design, optimized code allows optimized magnetic bearing geometries to be generated faster with fewer iterations;

五、Advanced graphical user interface

Tsino-Tek has developed an original graphical user interface that provides customers with an intuitive way to use the inherent advantages of magnetic bearing systems. The interface is continuously improved and upgraded based on customer feedback, giving you insight into all aspects of magnetic bearing and machine performance. It is a platform for system setup, monitoring and diagnostics:

Automatic mechanical clearance check;

Automated electrical connection testing;

To suspend the rotor to any desired position to meet operational or testing needs;

Debugging is made easier with built-in transfer functions and frequency response tools;