0755-23321087

1. Comparison between vector control and variable voltage and variable frequency control

Vector control VC | Variable voltage and variable frequency control V/F | |

Dynamic response speed | quick | slow |

Adaptability of speed to load changes | strong | weak |

Robustness against external disturbances | strong | weak |

Control Algorithm Complexity | high | Low |

Steady state control accuracy | high | Low |

Start and stop characteristics | good | poor |

torque ripple | Low | higher |

drive cost | high | Low |

Motor speed range | wider | wide |

Motor parameter sensitivity | high | Low |

Both controls have their own advantages respectively and can be selected for different application scenarios. Generally speaking, the scenario with priority of control effect is suitable for the drive of vector control, and the scenario with priority of cost is suitable for the converter of variable voltage and frequency.

The development of motor control technology also follows the Olympic Motto of "higher, faster, stronger". In addition to pursuing "higher" motor speed, "faster" dynamic response and "stronger" load capacity are also important characteristics of motor operation. Under the same conditions, vector control has "faster" dynamic response and "stronger" load capacity than variable voltage and variable frequency control.

2. Vector Control (VC)

Vector control is a control method with good control effect but high difficulty. It is currently widely used in CNC machine tools, industrial controls, robots and other fields that require high control performance.

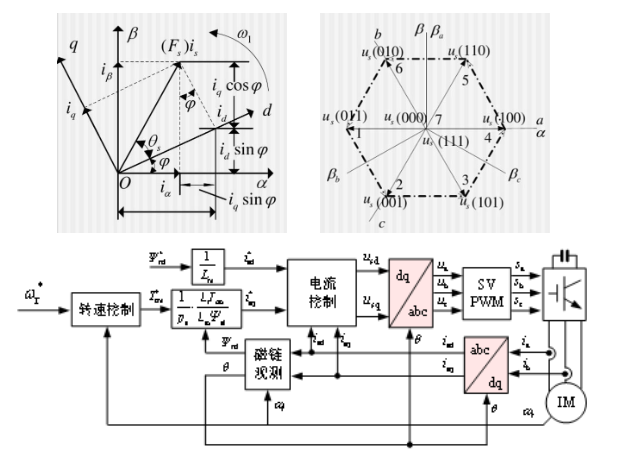

After a sinusoidal current is input to a three-phase AC motor, a rotating magnetic field is generated in the air gap. This magnetic field interacts with the rotor magnetic field to generate torque. Since the AC motor is a complex system with multiple variables and strong coupling, the independent control of the magnetic field or torque cannot be achieved by adjusting the current of a certain phase, which causes great difficulties in the control of the AC motor. In order to solve this problem, K.Hasse of Technical University of Darmstadt in Germany and F.Blaschke of Siemens proposed to decompose the stator current of AC motor into currents of magnetic field components and torque components through coordinate transformation in the 1970s, where the 2 current components are controlled separately to obtain the control characteristics similar to the DC speed control system. This method is Field Oriented Control (FOC). Because this method uses vectors to represent physical quantities such as three-phase voltage, current and flux linkage, it is also called vector control (VC).

There are three ways of magnetic field orientation: rotor magnetic field orientation, air gap magnetic field orientation and stator magnetic field orientation. Among them, the rotor magnetic field orientation is the most widely used. Both the air-gap magnetic field orientation and the stator magnetic field orientation are coupled in the flux linkage relationship, and the decoupling control of the flux linkage and torque cannot be fully realized. The rotor magnetic field orientation can decompose the stator current of the AC motor into the magnetic field component current (excitation current) and the torque component current (load current), where the currents are controlled separately. That is, the excitation current component and the torque current component are completely decoupled, so as to obtain the dynamic performance similar to the DC speed control system, and its controllability is optimal.

Features of vector control include:

(1) "faster" dynamic response

‐ Current, speed and position are all controlled by closed-loop, with fast dynamic response, high steady-state control accuracy, adaptability of motor speed to load changes and strong robustness against disturbances

(2) "stronger" load capacity

‐ Strong output torque capacity per unit current, being able to output larger torque with smaller current

‐ Together with the excellent dynamic response characteristics the motor speed will not drop under load increase.

(3) Inhibit heat generation, high energy conversion efficiency

‐ Under the same torque, the vector control brings about smaller current and lower copper loss of the motor

‐ Vector control can flexibly control the main magnetic flux, reduce the magnetic load of the motor under light load conditions and reduce the iron loss of the motor

‐ The current harmonic content of vector control is small, reducing the additional loss of the motor

(4) Complex algorithm and high precision

‐Using a multi-loop control structure: the inner loop is a current loop, which is used for closed-loop control of magnetic field and torque; the outer loop is used for closed-loop control of speed or position

‐The algorithm of the vector control system is complex. It needs to measure or calculate the speed of the motor and the position of the rotor flux linkage in real time, and perform coordinate transformation at the same time, which requires high computing power of the processor.

(5) Not easy to get into overcurrent

‐ It can directly control the motor current and limit the starting and braking current

‐ Under the same torque the current is smaller, coordinating the dynamic response in real time adjustment to reduce the probability of current overload

(6) Sensitive to motor parameters

‐ Parameters such as resistance and inductance of the motor need to be measured for control. In case the drive parameters are much different for different motors, it needs to be re-adjusted and adapted.

3. Variable voltage and variable frequency control (V/F)

V/F control is simple to implement, but has poorer control performance. It is often used in fields such as fans and pumps that do not require high control performance.

Since the back EMF of the induction motor is proportional to the product of its synchronous angular frequency and the air-gap flux linkage, ignoring the stator impedance voltage drop, it can be approximately considered that the motor voltage is proportional to the product of its synchronous angular frequency and the air-gap flux linkage (magnetic flux). When the motor speed is changed by reducing the frequency, if the motor voltage is not adjusted, the air gap flux linkage of the motor will increase. When the motor is working at rated conditions, the main magnetic flux of the motor is close to saturation, the continuous increase of the flux linkage will lead to the oversaturation of the main magnetic circuit, resulting in a sharp increase in the excitation current, an increase in iron loss, and even an overcurrent of the motor. When the frequency is adjusted the motor voltage is also changed proportionally, the air gap flux linkage can be approximately kept unchanged. Thereby the above-mentioned problems can be avoided. This control method is called variable voltage variable frequency control (V/F), also known as constant magnetic flux control.

Key features of V/F control include:

(1) Low cost

‐ V/F control is an open-loop control method, commonly used in induction motor control with low cost

(2) Insensitive to changes in motor parameters

‐ Only the motor nameplate parameters are required for motor operation, the control application is simple

(3) Low precision and slow dynamic response

‐ Due to the open-loop control, the steady-state control accuracy of the system is not high, and the dynamic response speed is slow

‐ When the load changes or is subject to external disturbances, the motor speed will change greatly, and the speed will drop or even fail to stop.

(4) Easy to get into overcurrent

‐ It can not control directly the motor current and can not limit the current at starting and stopping

‐ When the motor is overloaded, it is prone to cause overcurrent resulting in the equipment overloaded and shut- down or even damage.

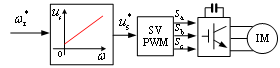

V/F control principle block diagram