0755-23321087

When it comes to high-speed motors, people are generally confused. How high of the motor speed is actually considered as a criterium for high-speed motors, what is the difference between them and ordinary motors, and what are the difficulties in design and application? In this article, Tsino-Tek presents you a detailed look into high-speed motors.

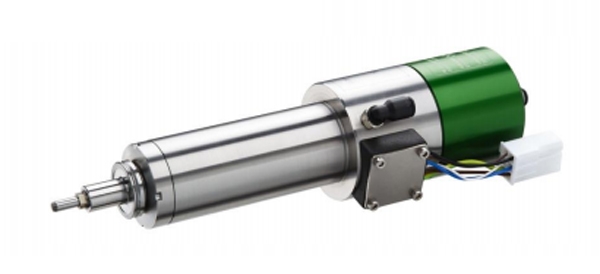

The so-called high-speed motor is a motor with a high speed. Generally speakinga motor with a speed of more than 10,000rpm is a high-speed motor; considering the size of the rotor there are also high-speed motors that can be distinguished from the surface speed of the rotor. In addition, some people think that motors with a speed-to-power ratio greater than 1,000rpm/kW are considered high-speed motors. The high-speed motor mentioned in this article refers to those motors that would be in a difficult position to meet the high-speed requirements by using general motor design and manufacturing technology, and must be specially considered.

It is presented in the motor design that the speed of the motor is closely related to the volume and weight of the motor. The higher the speed of the motor is, with the same power, the smaller the volume and weight of the motor can be reached. Along with the rapid development of motor technology and power electronics technology, people pay more and more attention to high speed. Many high-speed devices are expected to be free from the gearbox and to be driven directly by high-speed motor (so-called "direct drive") to compact the system, lower the costsand improve the efficiency. As to the motor itself, it is also expected that the volume and weight of the motor can be reduced by increasing the rotational speed to lower the cost. Therefore in recent years the demand for high-speed motors has been increasing and many manufacturers have also done business in the name of high-speed motors. However, it is difficult to find technically matured shelf products when an order is to be placed. Why does this happen? As mentioned before, the development and application of high-speed motors is different from the one of ordinary motors, and is extremely difficult. The difficulties in the design and application of high-speed motors are to be presented below.

1. Bearing limitations. Rotating electrical machines are inseparable from bearings. In addition to the load capacity, there is an important constraint for traditional bearings, namely DN value. The so-called DN value is the product of the diameter of the bearing and the rotational speed. Generally speaking the DN value of the bearing cannot exceed 2*10^6. If the motor speed is too high and the power is relatively large, the motorwill inevitably be restricted by this value and the general bearing cannot meet the requirements. To solve this technical problem, there are two aspects to be considered. On the one hand, the bearing industry needs to improve its technology, but the international cutting-edge bearings are basically foreign brands. One the other hand, it is necessary to find a different way by adopting some new technologies, like gas bearing, magnetic bearing etc.. The magnetic suspension bearing developed independently by Tsino-Tek possesses has excellent performance and can solve the bearing problem of high-speed motors.

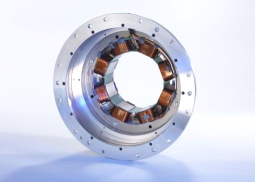

2.Rotor construction limitations. When the rotor rotates at high speed, the parts of the rotor will inevitably be affected by strong centrifugal force, as well as the radial and tangential electromagnetic force of the air gap magnetic field. If the speed reaches some level, the construction strength of related components will be limited, especiallythe rotor winding end, the fastening structure of the magnetic steel, the slot root, the slot wedge, the magnetic pole fastening structure, the rotor cast aluminum structure or copper bar welding, the commutator and other components and structures will be restricted. The traditional design and fastening measures can no longer meet the requirements, special design and technology must be adopted to ensure it. New technologies to solve this problem include high-strength stainless steel sleeve, magnetic steel embedded design technology, high-strength glass fiber hoop technology, high-strength carbon fiber hoop technology, new welding technology, high-strength silicon steel material technology, solid rotor technology, etc.

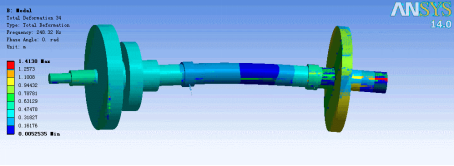

3. Rotordynamic limitations. Generally the speed of the motor is much lower than the first-order critical speed of the rotor structure, which is called "rigid rotor". It is not necessary to consider the vibration mode and deformation of the rotor above the second-order. But the speed of the high-speed motor may exceed the first-order or even the second-order critical speed, the rotor structure is then called "flexible rotor". The rotor of such kind is as soft as noodles when it rotates. Therefore it is necessary to carry out accurate dynamic analysis and calculation of the rotor and to take corresponding restraint measures. The required technologies include accurate simulation calculation of rotor dynamics, balancing technology of flexible rotors, and rotor stiffness balancing technology etc..

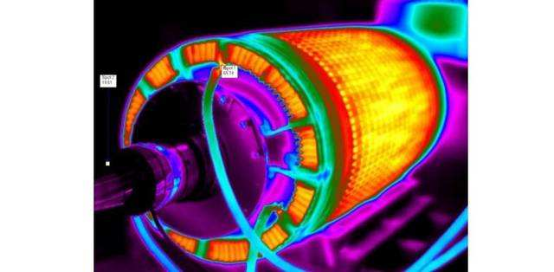

4. eat generation and cooling limitations. High-speed motors have outstanding advantages in small size and weight. But a reduction in size will inevitably lead to a reduction in the heat dissipation area, whereas the efficiency of the motor will not be much different, which means that the losses (i.e. heat generation) of the same power motors are of no much difference but the ones of the heat dissipation area are quite different. Therefore the problem of cooling and heat dissipation of high-speed motors is very prominent. On the other hand from the perspective of motor heat generation, due to the extremely high speed of the motor the frequency is usually very high and the iron loss is proportional to the 1.3th ~1.5th power of the frequency, hence the increase in iron loss will be very prominent. Besides, the extreme high-speed will deteriorate ventilation losses and stray losses dramatically. On the one hand the heat dissipation gets worsed, on the other hand the heat generation does not stop. In addition the fastening structure of the rotor needs to be hooped or inlaid with a stainless steel sleeve. The stainless steel sleeve is a good metal conductor, which will increase the stray losses of the rotor. Both FRP and carbon fiber as sleeve material are poor conductors of heat. The superposition of various factors makes the temperature rise of high-speed motors be a very difficult problem. Solutions for the problem include precise electromagnetic and thermal calculation technology, advanced cooling technology (such as evaporation cooling technology etc.) and cooling structure, advanced material technology etc.

5. Vibration and noise limitation. Vibration and noise are important technical indicators of motors. High-speed motors have high excitation frequencies due to high speed. In addition because the motors are slender, light in weight, relatively small in damping and numerous in vibration mode, it is more likely to generate vibrations of various frequencies. Vibration is the source of noise. If the vibration is large, the structure noise will inevitably be large. Due to extremely high speed, it is likely to generate large air noise. During tests, it often happens that the vibration and the noise are too large to carry on the tests before the specified speed is reached. Therefore it is a problem to be resolved compulsorily with high-speed motors, namely vibration and noise reduction. Indeed is the problem is also particularly a difficult one to be solved. It needs to be comprehensively considered in electromagnetic design, structural design etc...

6. Structural size limitations. Theoretically the smaller size of high-speed motors is the biggest advantage. But compared with low-speed motors if the power and the voltage of the motors are the same, the current will be the same or similar and the cross-section of the employed lead cables will not be smaller. , In relatively low-speed motors, because of the larger size of the motor there is enough space to arrange the lead cables and there is often no problem with the cable lead-out. While the internal space of high-speed motors is small, especially at the winding end, there is often no space to accommodate cables of bigger cross-sections. Thereforethe cable lead-out of high-speed motors becomes a big problem and must be specificallyconsidered. It even has to enlarge forcedly the size of the high-speed motor, which greatly lowers the advantage of small size of high-speed motors.

7. Control limitations. High-speed motors are usually controlled by converters. Due to the extremely high rotational speed the fundamental frequency is accordingly very high, while the switching frequency of power electronic devices is limited and if the switching frequency is too high, the electronic components will get heated up excessively and the converter efficiency will decrease. At a certain switching frequency, a modulated higher fundamental frequency will inevitably lower the modulation index, increase the harmonics,and worsen the waveform, which further deteriorates the heat generation and efficiency of the motor, thus restricting the further improvement of the speed. Usually converters for high-speed motors require specific design. Tsino-Tek high-speed motor drive is specifically designed for high-speed motors. High switching frequency can decrease motor heat generation and improve control performance.

8. Machining limitations. The requirement of dimensional fit tolerance for high-speed motors is high., as well as the requiremet of geometric tolerance and roughness. To ensure it presise machining equipment and process technology are required accordingly. In addition, many special designs of high-speed motors are often guaranteed by special process technologies, such as special welding processes (ion beam welding, electron beam welding, friction stir welding etc.), carbon fiber hooping process, precision thin-wall parts machining process, high-speed dynamic balancing process, etc.

9. Material limitations. As mentioned earlier, high-speed motors will involve the application of many new materials, such as high-strength and low-loss magnetic materials, high-temperature-resistant rare-earth permanent magnet materials, high-strength glass fiber and carbon fiber materials, high dv/dt insulation materials, and so on.

10. Electro Magnetic Compatibility limitations. The fundamental frequency of high-speed motors is already very high and the high-order harmonics are relatively large, which makes the electromagnetic emission energy larger. Not only the conducted emission is large, but also the high-frequency radiation becomes a key factor to be considered, otherwise it will cause electromagnetic interference to surrounding electrical equipment. Furthermore, because of the extreme high speed of high-speed motors, in order to control it precisely not only sensors with extremely high resolution are required, but also the frequency of the control signal will be higher and the dynamic performance of the controller will be higher, which will inevitably result in a high sensitivity of the controller. The anti-interference ability becomes poor. Therefore, the electromagnetic compatibility performance of high-speed motors is also a problem that cannot be ignored.

Although high-speed motors are in high demand, butit is extremely difficult to produce actually matured products due to the abov-mentioned reasons. Qingzheng Yuanhua (Beijing) Technology Co., Ltd. focuses on the research and development of high-speed motor drives and provides customers with high-quality customized services.