0755-23321087

TSD high-speed motor drive, specifically designed for high-speed applications, can effectively reduce the losses of high-speed motors, as well as the heat generation. Compared with domestic and foreign competing products, the losses of the motor at high-speed operation can be significantly reduced and the system efficiency can be significantly improved. For high-end users who pursue low motor heat generation and high system efficiency TSD high-speed motor drives are worth of application.

Relevant studies have shown that 90% of the losses caused by the drive to the motor will be imposed on the rotor, and these losses will cause the accumulation of heat to damage the motor. The high-speed application scenario further limits the size of the motor and puts forward higher requirements for the heat dissipation of the motor. TSD high-speed drive can reduce the harmonic current of the motor, which can significantly improve the temperature rise of the motor and the machining accuracy. In addition, the low temperature rise of the motor can also prolong the service life of the ball bearing.

As mentioned earlier, TSD high-speed drives reduce motor heat generation by reducing ripple current, which is primarily dependent on switching frequency, drive BUS voltage and motor inductance. For high-speed motors the inductance is generally small and the ripple current is large. The drive BUS voltage mainly depends on the rated voltage of the motor, which is basically difficult to adjust. The only one that can be adjusted is to increase the switching frequency. The higher the switching frequency reaches, the smaller the motor ripple current is. Simply by increasing the switching frequency the ripple current can be reduced, but the control frequency of competing products is limited by the performance of the controller and hence cannot be improved continually , resulting in poor control performance and unstable rotational speed.

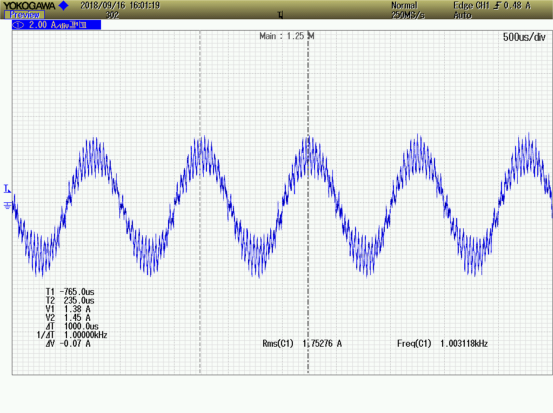

Competitor corresponding model drive @ 60,000 rpm current waveform

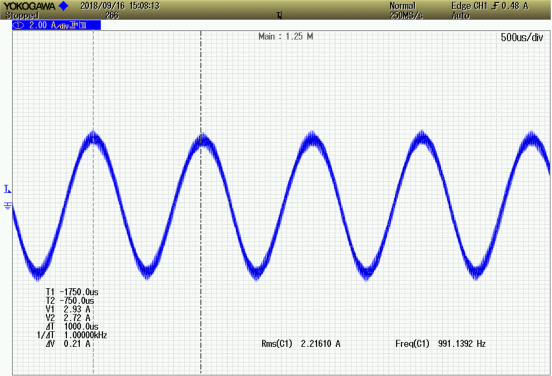

Tsino-Tek ultra-high-speed drive@60,000rpm current waveform

TSD high-speed drive can achieve smaller ripple current. The reason is that it adopts the system platform of "5-generation motor control technology + GaN/SiC power device", the switching frequency can reach 128kHz and the maximum output is 8,000Hz (corresponding to 480,000 rpm). The 5-generation motor control technology adopts SoC FPGA parallel acceleration vector control, which can improve control accuracy and reduce current harmonics so that the speed of the motor/electric spindle does not drop under load increase, the torque is high and the temperature rise is low.The performance is significantly far ahead of the mainstream 4-generation DSP control technology.

Relying on the unique control algorithm TSD high-speed drive can provide customers with better performance, higher speed and lower motor temperature, promoting customers to achieve more efficient and safer high-speed motor control.